Secure glass panes against falling over

ELOOSAFE tension clamp for pallets

7.1 » 7.0 | ELOOSAFE tension clamp

Why use the Eloosafe tension clamp?

Hold on a minute…

…Do you know how expensive this set can be? How often do your employees move a pallet where there is a risk of the goods tipping over? In this case, tape is sometimes stuck around the entire pallet or an employee has to secure the goods by holding on to them. No matter what is done, you lose money.

Alternative: The Eloosafe transport safety clamp. It secures goods during in-house transport or on construction sites where upright products are installed.

Not only goods, but also employees are protected. Perhaps you have already experienced a good breeze on the building site or at an open hall door. This gust of wind is capable of causing a pane of glass to tilt. If a person is standing or walking where the heavy pane falls, the result can be very serious injuries.

The fact is, no matter what happens, the time you lose repairing the damage alone will cost you more than the Eloosafe fuse clamp.

7.2 » 7.0 | ELOOSAFE tension clamp

Model overview of the fuse terminals

Model overview

The Eloosafe disc safety clamp is available in 2 different lengths and 3 different pressure variants.

This currently includes (soon also for metal frames):

ES-60-PAL = 60 cm long arm with 2 castors.

ES-60-P-PAL = 60 cm long arm with continuous pressure profile

ES-60-PL-PAL = 60 cm long arm with pressure plate

ES-100-PAL = 100 cm long arm with 2 castors.

ES-100-P-PAL = 100 cm long arm with continuous pressure profile

ES-100-PL-PAL = 100 cm long arm with pressure plate

Clamping clamp with pressure rollers

Clamping clamp variant with pressure roller:

ES-60-PAL and ES-100-PAL

The 2 pressure rollers reduce the risk of shiny spots on the product to be secured. The rollers touch down on the product surface first. If you press the lever arm further or with more force against the product, the rollers simply rotate with it. With the clamp with a continuous profile (ES-..-P..), the pressure point would rub on the product surface. The distance between the two pressure rollers also makes it possible to position the safety clamp on uneven or perforated surfaces.

Clamping clamp with continuous pressure profile

Clamping clamp variant with continuous pressure profile:

ES-60-P-PAL and ES-100-P-PAL

The clamping arm of this safety clamp is fitted with the flexible PVC profile familiar from metal racks. The pressure point is not quite as punctual as with the disc clamp with rollers. The continuous profile also offers the advantage for smaller or lower products that the clamping arm protects and secures your product. However, the roller clamp can also offer this advantage if the clamping arm is covered with felt, for example.

Clamping clamp with pressure plate

Clamping clamp variant with pressure plate:

ES-60-PL-PAL and ES-100-PL-PAL

Our product securing clamp for pressure-sensitive surfaces / goods such as very sensitive, thin metal sheets or cardboard packaging. The 20 x 20 cm HPL pressure plate is made of 8 mm thick HPL and always rotates in line with the product surface thanks to its axial attachment to the clamping arm. We deliver the plate without any protection. This can be stuck on individually. Here you can see 2 felt strips as an example. Cork tiles or a full-surface covering with felt, anti-slip rubber … can certainly be realised without any problems.

7.3 » 7.0 | ELOOSAFE tension clamp

Function of the Eloosafe glass clamp

Positioning the tension clamp

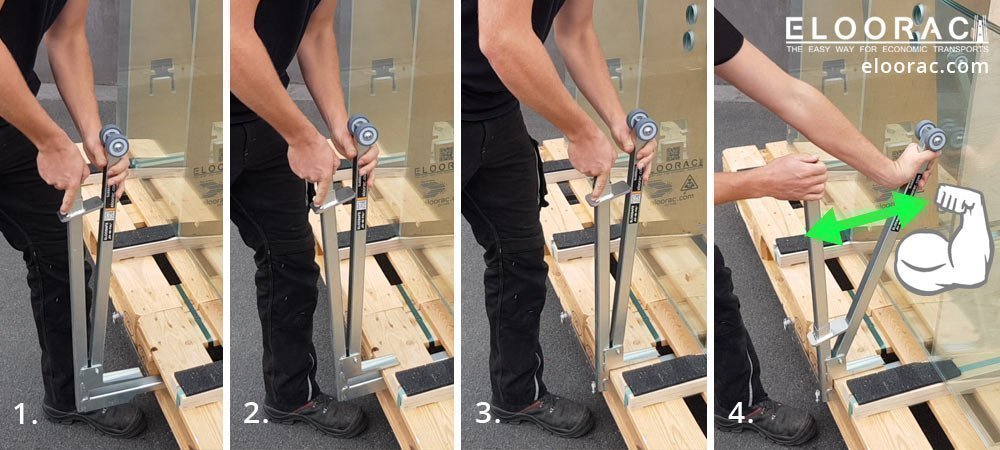

How to use the glass pane clamp?

The Eloosafe safety clamp is simply pushed onto the top board of the Euro pallet and the two upright metal struts are pressed apart. The small clamping iron slides down in the same breath so that the clamping arm can maintain its pressure against the product. Done. The simple clamping mechanism not only ensures safety but also saves an enormous amount of time.

Note: Force must be applied when pushing apart. But not too much!

Attach and detach

Fastening and releasing the tension clamp

As this is a “clamping device”, force must be applied when pushing the upright standpipe and the movable clamping arm apart. To avoid damaging the product, this force should not be too great.

When releasing the clamp, press your elbow against the product and your hand against the upper end of the upright standpipe. In this way, the clamping arm is relieved and no longer exerts any pressure on the product. The clamping bar, which had previously slipped downwards, can now be pushed upwards and the clamping arm returned to its original position.

Securing and scrolling with pressure roller

We have already explained the area of application of the tension clamp with pressure roller above. Here is an example of how the disc clamp can be used not only to press on / hold the product, but also to “browse” through all the products, for example.

There is often a situation where different sizes of wooden panels, façade panels or glass panes are placed on the glass rack and not the front pane is required, but one from the centre or from further back. You then simply flick one panel after the other forwards against the safety clamp and can then remove the desired part.

Securing and scrolling with pressure plate

Safety clamps with pressure plates are not only used for pressure-sensitive products such as cardboard packaging or thin sheet material. As you can see, the pressure plate can also be used for less sensitive surfaces.

The “scrolling” function is used, for example, when goods that are not labelled have to be subsequently provided with stickers. When it comes to glass panes, which employees often lean against their hips in order to apply a sticker to the next pane, too much strain can result in the panes no longer being able to be held in place, leading to serious injuries.

7.4 » 7.0 | ELOOSAFE tension clamp

Examples of the use of our clamping safety device

Secure high glasses

Secure tall glass panes with the Eloosafe glass pane holder on Eloorac transport racks.

In addition to the 60 cm small clamp, the use of the 100 cm long glass clamp is shown here. A combination of the short and long fuse terminal can also be realised. In our opinion, however, the long disc clamp is not absolutely necessary. Ultimately, this is about securing windows, front doors, wooden panels or glass in the factory or on the building site. Particularly high loads are therefore not to be expected.

Individual positioning of the tension clamps

Eloosafe tension clamps can be positioned individually.

The Eloosafe tension clamp can be positioned individually on pallets. With Euro pallets, our securing tool works on all top boards as well as on the cross boards underneath.

They can also be used on special pallets or one-way pallets or racks. Just make sure that the boards are not thicker than the Euro pallet.

Move long panels safely

An approx. 4.5 metre long wooden panel, which stands on an Eloorac transport frame, is held by the Eloosafe tension clamp and can therefore be moved safely through the factory. Of course, especially with such long products, care must be taken to ensure that the clamp does not come loose due to the rather long lever created by the large overhang in relation to the pallet.

Secure metal elements in a special shape

The Eloosafe safety clamp in use in the metal sector. The clamp with pressure rollers can be more helpful in certain situations than the alternative Eloosafe models due to its greater contact pressure width.