“RACK in the BOX” Transport racks

Sustainability through parcel returns

10.1 » 10.0 | RACK in the BOX

Returning transport racks in a carton? – Why?

Every day, not only online retailers use vast amounts of disposable transport racks to ship bulky goods such as radiators, fences, windows, glass, shower stalls, room doors, front doors, etc. to the customer. Each of these wooden racks is used only once. After that, it is burned or must be disposed of at great expense. Many companies require between 5,000 to 20,000 disposable wooden transport racks each year.

This means an enormous effort in production, planning and organization as well as recurring costs for purchasing, storage and logistics of these wooden racks. Some companies invest up to 500,000 Euros annually for the purchase of wooden racks for one-time use. That’s 2.5 million euros in 5 years for “disposable wood” per site. There is enormous potential for savings here.

The expenses that are usually spent on purchasing do not yet include the other organizational expenses listed above, which are likely to be as high again.

RACK in the BOX as XXL Transport Rack

The “RACK in the BOX” systems are now available in different versions. These differ in terms of pallet width, pallet length and rack height. In addition to short racks, it is also possible to create very long transport racks. As you can see here, these can also be driven under from the long side with a pallet truck. Additional connecting boards, which are attached between the two pallets, enable this stable connection. More in video no. 23.

“RACK in the BOX” Impressions

10.5 » 10.0 | RACK in the BOX

Spacer plates for different pallet lengths

Customised frame lengths thanks to spacer plates

The illustration shows a transport rack that has been extended to a length that could not otherwise be achieved with standard Euro pallets using spacer plates. The boards are simply held between 2 pallets or placed on the pallets using additional auxiliary strips and then pulled together with PET strapping and a lashing device to form a tight bond.

Possible pallet lengths with spacer plates

“RACK in the BOX” Variants in a quick overview

10.3 » 10.0 | RACK in the BOX

“RACK in the BOX” Details for…

… racks in wide cardboard boxes:

A

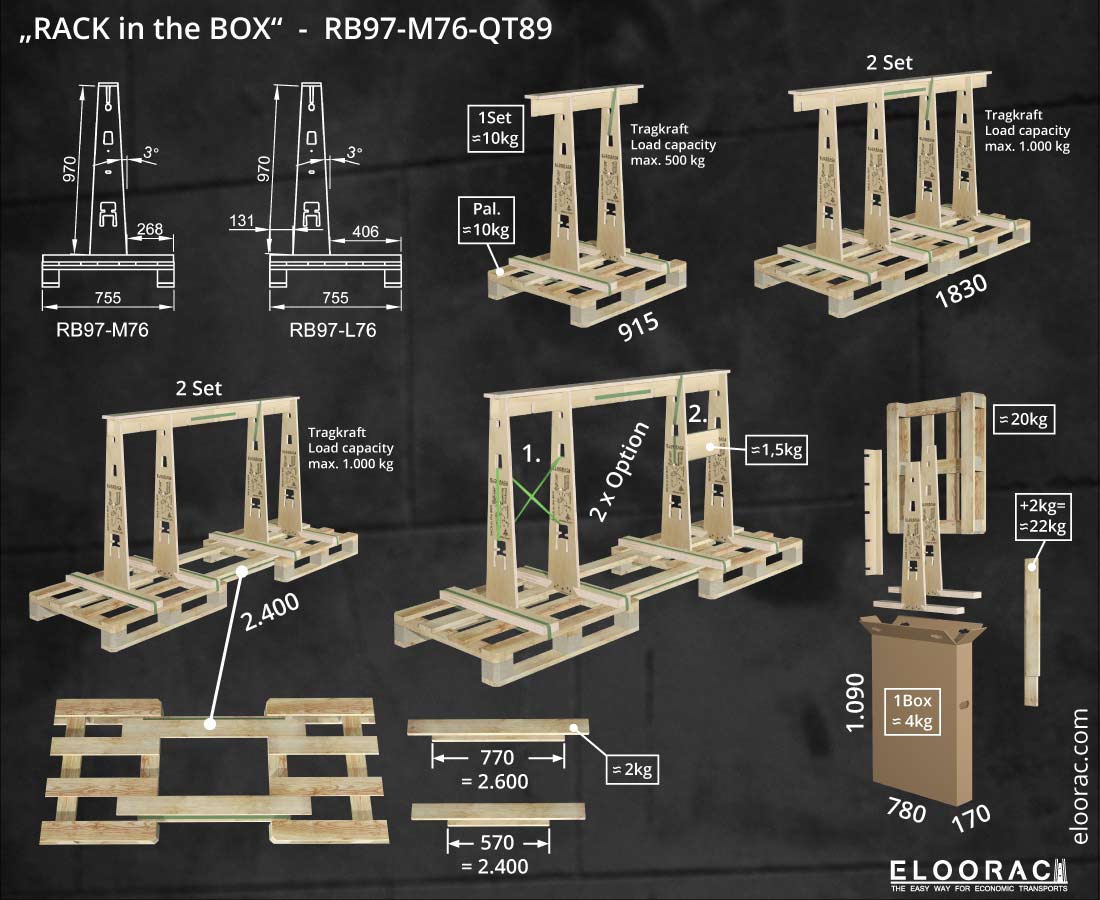

RB97-M76

low, wide, on special pallet

– Special pallet 91.5 x 75.5 cm

– 97 cm high (contact edge)

– 54 cm storage area (“M” 27/27 or “L” 13/41)

– wide carton

B

RB97-M76 – EPAL

low, wide, on EURO pallet

– Euro pallet 120 x 80 cm (exchangeable)

– 97 cm high (contact edge)

– 54 cm storage area (“M” 27/27 resp. “L” 13/41)

– wide carton

C

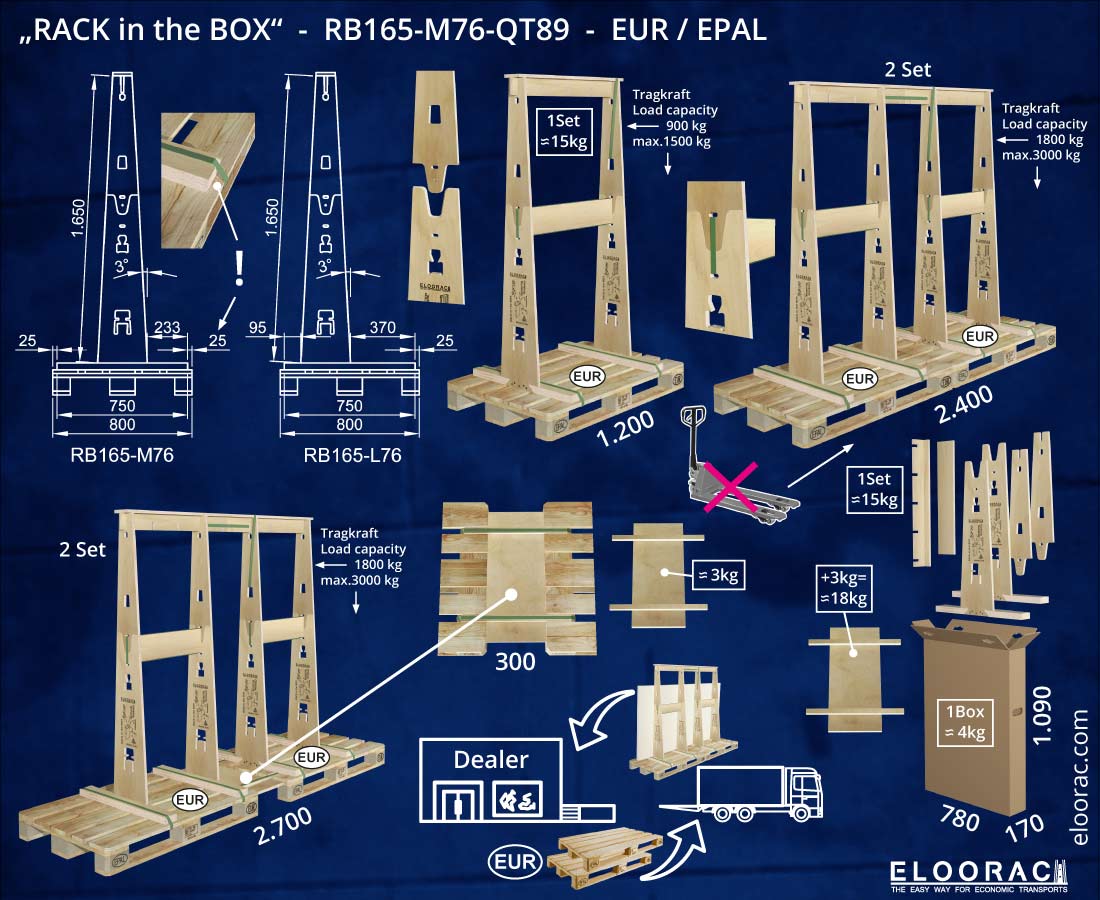

RB165-M76

high, wide, on special pallet

– Special pallet 91,5 x 75,5 cm

– 165 cm high (contact edge)

– 46 cm storage area (“M” 23/23 or “L” 9/37)

– wide carton

D

RB165-M76 – EPAL

high, wide on EURO pallet

– Euro pallet 120 x 80 cm (exchangeable)

– 165 cm high (contact edge)

– 46 cm storage area (“M” 23/23 resp. “L” 9/37)

– wide carton

… racks in narrow cardboard boxes:

E

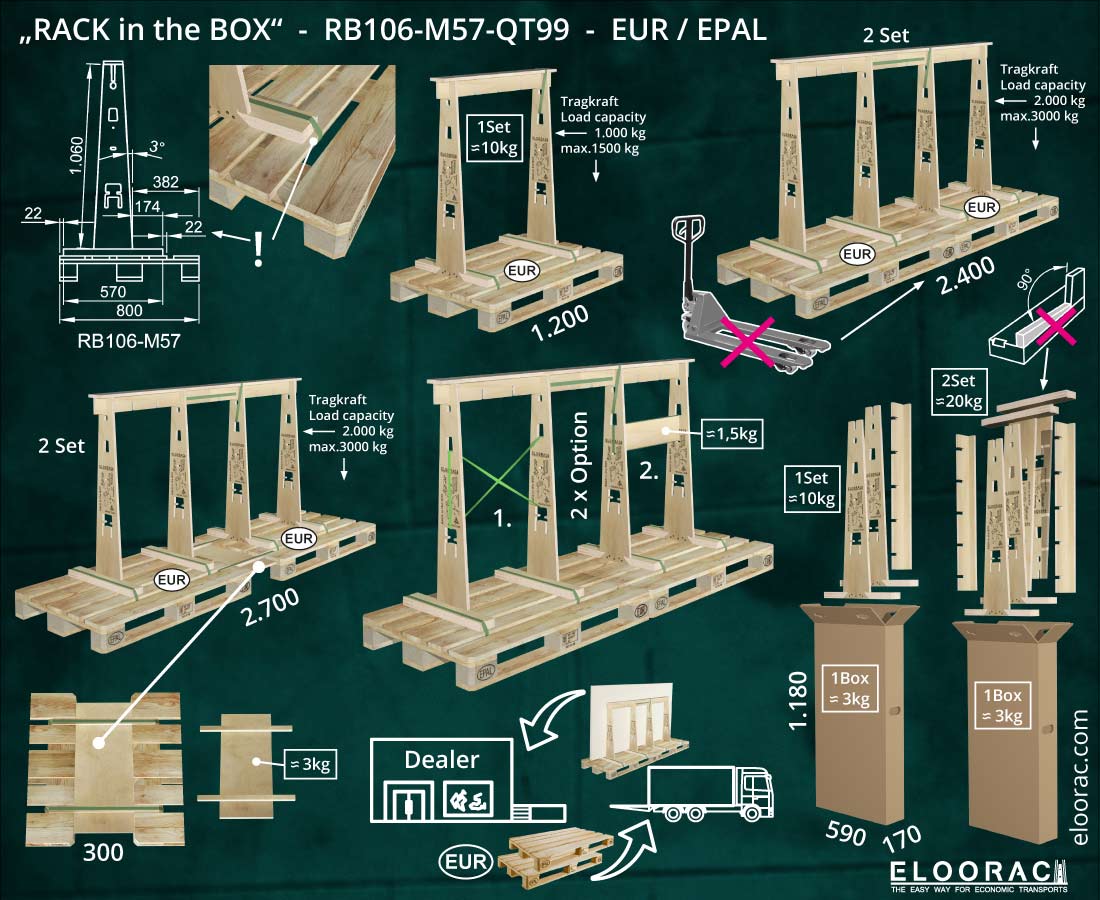

RB106-M57

low, narrow on special pallet

– Special pallet 106 x 57 cm

– 106 cm high (contact edge)

– 34 cm storage area (17/17)

– narrow cardboard box

F

RB106-M57 – EPAL

low, narrow on EURO pallet

– Euro pallet 120 x 80 cm (exchangeable)

– 106 cm high (contact edge)

– 34 resp. 55 cm storage space (17/17 resp. 17/38)

– narrow cardboard box

G

RB165-M57

high, narrow on special pallet

– Special pallet 106 x 57 cm

– 165 cm high (contact edge)

– 28 cm footprint (14/14)

– narrow cardboard box

H

RB165-M57 – EPAL

high, narrow on EURO pallet

– Euro pallet 120 x 80 cm (exchangeable)

– 165 cm high (contact edge)

– 28 or 49 cm storage area (14/14 or 14/35)

– narrow cardboard box

10.4 » 10.0 | RACK in the BOX

Retrieval of the disassembled transport racks

The fact that you can dismantle a transport frame that weighs several hundred kilos and pack it into a cardboard box, which is then sent back to you by a parcel service, actually makes you think a little. After all, the pre-packed box only weighs between 20 and 30 kg.

This means that a tool that can be used to transport goods weighing 400 kg, for example, only weighs a small proportion of this weight itself. Sounds crazy, but it works. Renowned companies are already successfully using the “RACK in the BOX” system.

Picture guide for repatriation

Suitable return instructions for every system

Do you think the “RACK in the BOX” transport system is really interesting, but you’re not sure how to explain the return to your customer? No problem. We can help you.

The illustration you see here shows an overview of instructions for the various “RACK in the BOX” constellations. Of course, your customer will only receive one of them. In our download area you can download each manual individually as a PDF. Click here to download the desired documents: Return instructions

However, the question now arises as to how the retrieval can be organised. As always, there are various approaches and solutions to this problem.

1. your customer takes the packed box to a parcel shop themselves. This is certainly the simplest solution for you. Unfortunately, not all customers are prepared to go to this trouble. Do you have such a customer? Look after him, that’s a good one…

2. the customer calls you or sends you an e-mail and informs you that the box can be collected. For smaller quantities, this procedure can certainly be implemented without any problems.

3. you create a website with a form that asks for all the information needed to collect the box. The company GilgenDoors has kindly allowed us to mention or link to their “collection page” here:

https://www.gilgendoorsystems.com/return

Such a form can usually be created quite quickly by a web designer.

As a service, Eloorac offers the use of a “return form”, which asks for the most important information and enables you as the sender to instruct a parcel service of your choice to collect the parcel(s).

Click on the link here or scan the QR code. Both will take you to the test account collection form:

https://get-back-my-rack.com/?code=123MuellersExample456

At this point you have a lot of questions. Give us a call or send us an e-mail. We are happy to help.

Tel: +49 (0) 52 44 – 97 46 56

Mail: info@eloorac.com

QR code to the response form

10.5 » 10.0 | RACK in the BOX

Take advantage of the moment – Be better than others

You should see the new “RACK in the BOX” as a chance. Draw attention to yourself with our sustainable system. Show your customer that not only you, but also he has advantages with the new “transport system in the box”.

Arguments in favour of using the “RACK in the BOX”

1. first of all YOUR big advantage: you buy the system once and use it again and again. Disposable systems have to be bought again and again or created again and again. This is very expensive in the long run. If you want to know how long Eloorac transport racks last, we can only give you one answer: We don’t know. Nobody has ever complained that an Eloorac transport rack has broken.

However, the pallet and box of the “RACK in the BOX” system will have a shorter shelf life. They will definitely have to be replaced after a few deliveries. As we do not see our existence in the carton or pallet trade, we are happy to give you tips on how to rebuild the pallets or what the cartons should look like.

2. sustainability is currently on everyone’s lips. Let your customer know that they are making a significant contribution to a sustainable future by helping to return the transport rack.

Point out that other retailers/competitors are not using such environmentally orientated solutions. The customer must have the feeling that it is better to order from you and thus automatically do something for the environment.

3. communicate openly and clearly on your website that the customer will not be left with a pile of rubbish on their doorstep. All they have to do is pack the transport rack and pallet into the return box according to the enclosed instructions.

The return costs of the 20 to 32 kg boxes are definitely a joke compared to the return costs of other systems. It is up to you to decide who bears these costs. The fact is that when it comes to reuse and collection, no other system can keep up.

4. outdo your competitors by pointing out to the customer that other sellers do not collect the waste. Capitalise on this advantage.

5 In the long run, your competitors’ products will have to be more expensive. Reason: More and more customers will learn that they have the right to have their disposable waste collected (Packaging Act). Your competitor will then have to add the collection costs to their sales price in advance. Score one for you. You are cheaper and more environmentally conscious.

6. the customer is happy to recommend you. Why? He is satisfied because he has made an environmentally friendly purchase and, above all, because there is hardly any waste.

7. positive reviews on your website, on Google, on social media… are guaranteed. That is worth GOLD.

8. incentivise your customers with a voucher. As there is minimal labour involved in packing the rack, you could offer the customer a voucher for X amount as “compensation”. This has the advantage that you can use the “RACK in the BOX” without any problems and that the next purchase will be made in your webshop. The customer receives the voucher after you have received the box including the rack. Another precision landing.

9. it will certainly happen that some customers like the rack so much that they use it to store other things. No problem. Today, every Euro pallet is only issued against a deposit. This works just as well with the “RACK in the BOX” transport rack.

10.6 » 10.0 | RACK in the BOX

And who disposes of the packaging waste?

Have you ever been asked this question? How many customers do you think ask this question every day? Wouldn’t it be great if you could offer them a solution by answering: “We’ll take care of that. We just need a little help from you. We work with a transport rack that you simply pack back into the box provided. It will then be sent back to us by parcel service.”

Who disposes of these one-way racks?

Are customers happy when garbage racks are in their gardens?

Reusable system “RACK in the BOX”

Alternative: The worldwide unique “RACK in the BOX” transport rack

The idea of “RACK in the BOX” was born a long time ago. When the packaging law “VerpackG” was passed in 2019 in Germany, we knew that we had to take action. The new law obliges to take back pallets, one-way racks and other transport packaging used for shipping by forwarding companies. The legislator has understood that something must be done against the throw-away mania in the transport industry.

Wooden racks must be taken back

What happens if the consumer has a disposable rack at his door and does not want to or cannot dispose of it? Here the packaging law Verpackungsgesetz “VerpackG”, existing since 01.01.2019 in Germany, says that the dispatching dealer is obliged to take back this one-way rack free of charge according to § 15 Abs. 1 Satz 1 Nr. 1 VerpackG. Source: www.it-recht-kanzlei.de